Edelmann Group

Outstanding packaging designs for innovative cardboard and paper packaging solutions for the Beauty Care, Health Care, and Consumer Brands industries.

Breathtaking packaging experiences for the beauty industry, health care, and consumer brands. Appealing designs that touch the heart and stick to the minds of consumers. Technical innovations that catapult the packaging industry straight into a sustainable future: That’s what the Edelmann Group stands for.

Since 1913, the traditional family-owned company has been designing and producing high-quality packaging solutions made from cardboard and paper, always holistically well thought-out. Performed at the highest technological level – and always aspiring to be both efficient and environmentally conscious. So, on the one hand, customers can optimize their processes throughout the entire supply chain and, on the other hand, reduce their CO2 footprint as much as possible.

A Sustainable Quality Partnership:

Outstanding packaging designs for innovative cardboard and paper packaging solutions for the Beauty Care, Health Care, and Consumer Brands industries.

Endless new possibilities in digital finishing. An innovation from our subsidiary, STEINEMANN DPE.

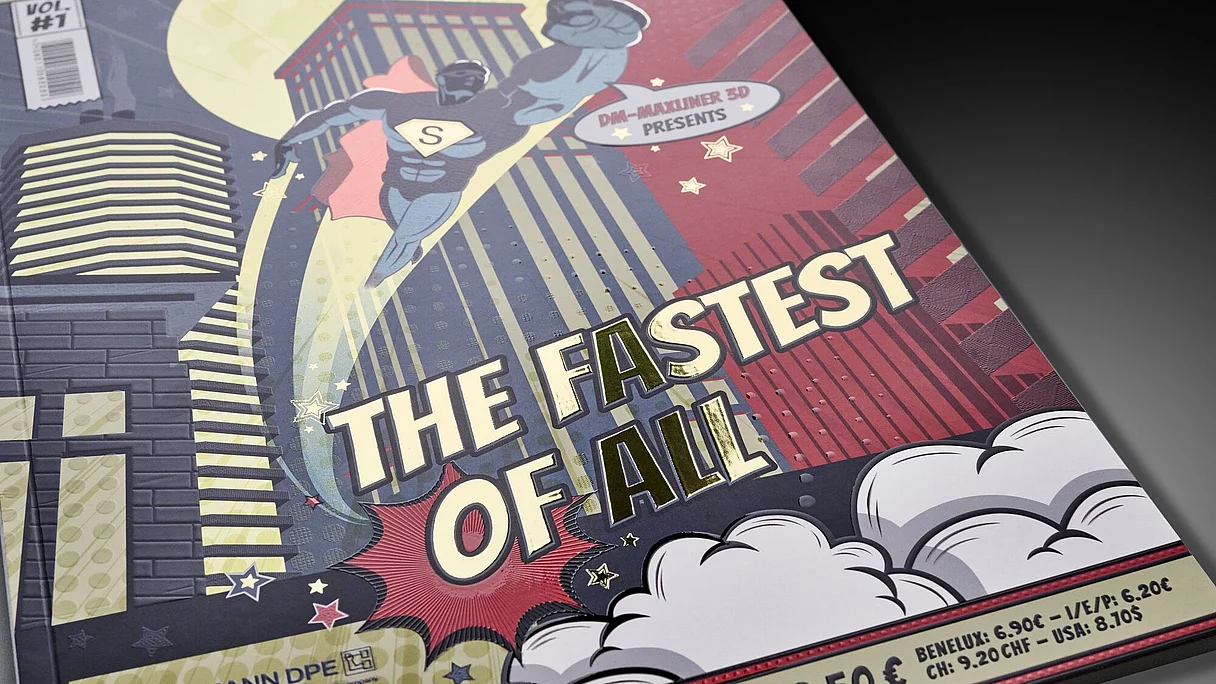

With maximum design freedom in digital print finishing, the Edelmann Group had set itself an ambitious goal: An endless amount of new ideas in packaging design needed to be feasible in offset printing. Practical and efficient production – regardless of the order volume. The solution was to be seamlessly integrated into the existing process landscape and tailored to sustainability. Certainly a challenging requirement package!

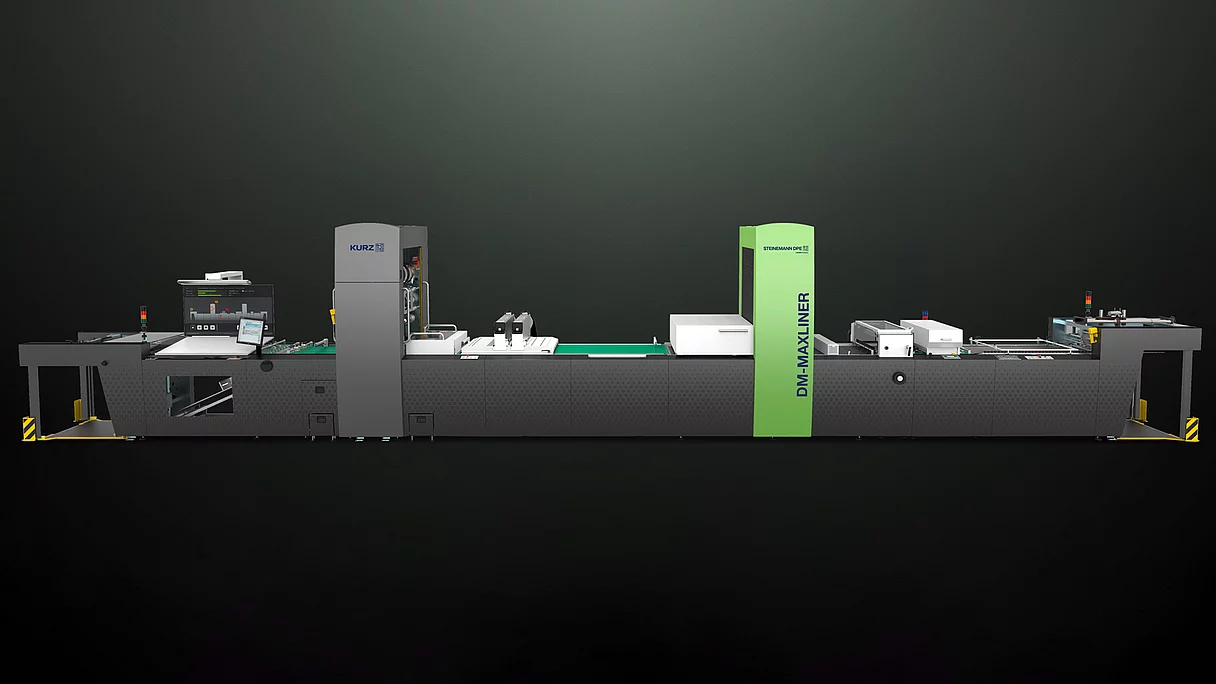

The modular DM-MAXLINER 3D offers an endless amount of new possibilities for packaging developers and designers. Our renowned subsidiary, STEINEMANN DPE, deploys two different finishing units in development. Digital metallizations and digital spot coatings – as haptic reliefs – are thus possible in just one work pass. The result is filigree metallized lettering and patterns, high-gloss spot coatings, or large-scale lacquer areas with a wide range of raised structures. This means enormous added value for branded products.

The efficiency is just as impressive: With up to 10,000 sheets per hour, the DM-MAXLINER 3D can keep up with the currently established classic printing presses and can quickly refine even medium-sized orders digitally. Set-up times are short. Maintenance times are low. How does that work? It’s all down to the years of experience and expertise of two renowned finishing experts who have teamed up especially for this project and have thus created a world first.

A beautiful idea: Returning the PET residues from transfer decorations to the recycling cycle instead of disposing of them. Even better: Rather than simply reusing it, for example as a simple planter, it is recycled in a high-quality manner. The Edelmann Group and KURZ have succeeded in putting this vision into practice.

With an investment volume of several million euros, KURZ has developed the PET recycling concept over three years and tested it together with the Edelmann Group. And it works: As a result, 35 metric tons of PET residues have already found their way back into production as a valuable injection molding material for the plastics industry.

Powerful machines, innovative application software, and resource-saving coatings plus recycling – as a one-solution provider in the field of digital finishing, which itself focuses on sustainability, KURZ and the Edelmann Group are two strong partners with similar values and visions.

“The DM-MAXLINER 3D sets new standards in terms of design freedom and process efficiency,” explains Wolfram Hahn, Global Business Development Manager at Edelmann. “The system from STEINEMANN DPE and KURZ is ideal for strengthening the future-driven positioning of our broad product portfolio. The technology expands our options for providing packaging materials with sustainable, environmentally friendly effects.”