- Home

- Technologies

- 3D Inkjet

One-pass digital embellishment with 3D inkjet

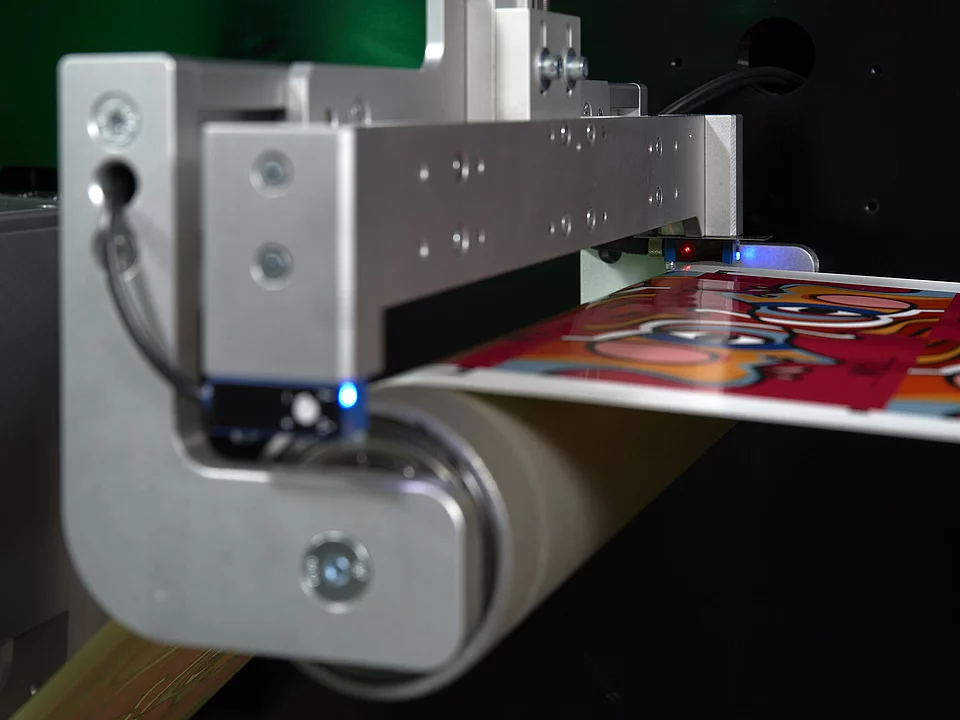

KURZ 3D inkjet technology – also known as Inkjet on Substrate – powers high-precision application of UV spot varnish and digital metallization in a single pass. This tool-free process allows you to create tactile, high-impact print products at an industrial scale with full creative control, consistent quality, and fast turnaround.

How KURZ 3D inkjet technology creates tactile embellishment

Explore how to achieve glossy spot coatings, tactile relief varnishing, and flat or raised digital metallization — perfect for large areas or fine detail. KURZ 3D inkjet technology uses digitally applied UV varnish and transfer foil to build precise, layered effects. Watch the animation to learn how it works.

What is the KURZ 3D inkjet technology?

Precise application with industrial power

KURZ 3D inkjet technology applies UV-curable varnish directly to the substrate with pinpoint accuracy. This produces high-resolution spot coating, relief varnish, and digital metallization in a single process step – built for scalable, industrial output.

Smart use of digital inkjet technology

3D inkjet builds up defined structures by digitally controlling varnish volumes. The varnish is inkjet printed only where needed, allowing fast, contactless application of raised effects with full design flexibility.

From data to embellishment

The process starts with your design file – no plates, no molds. Inkjet parameters control where varnish is applied, the thickness of varnish lay down, and where metallization will be added - enabling precise, variable embellishment at high resolution.

How it works: Achieve tactile and metallic effects

Step 1: Precise inkjet application of UV varnish

UV-curable varnish is ink-jetted directly onto the substrate with 600 dpi native resolution. Precise digital control from the first print.

Step 2: Building the structure

Varnish volume is digitally adjusted to control lay down and texture — from fine spot varnish to bold, tactile relief. Effects are applied with high repeatability, precision and control.

Step 3: Digital metallization for brilliant details

Metallized transfer foil is applied inline, bonding only to defined varnished areas. This creates sharp, high-gloss highlights — with no need for dies or pressure.

Ready to dive deeper into 3D inkjet and digital embellishment? Let’s start the conversation.

LEONHARD KURZ Stiftung & Co. KG

Schwabacher Straße 482

90763 Fürth/Germany