2D INKJET

Built for substrate versatility – Discover KURZ 2D inkjet technology

- Home

- Technologies

- 2D Inkjet

Experience innovation with the patented KURZ 2D inkjet technology

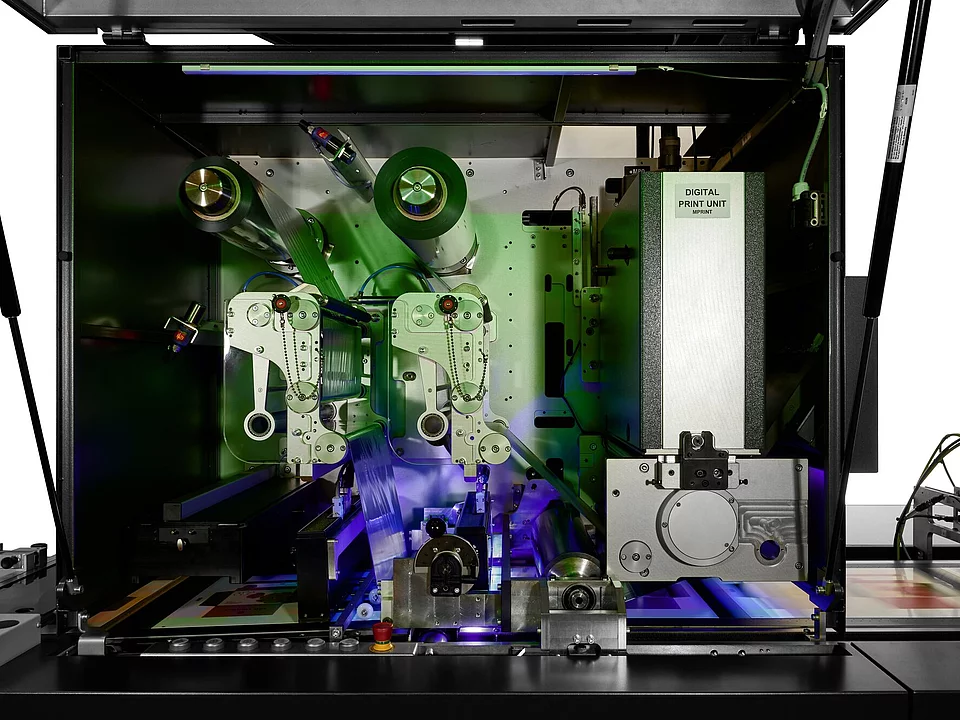

The patented KURZ 2D inkjet technology achieves precise digital metallization with consistently brilliant results across a wide variety of substrates. By applying UV adhesive to the reverse side of the transfer foil in a digital cold transfer process, rather than directly onto the material, it ensures stable, repeatable output — including on uncoated and textured papers. The result: reliable quality, reduced setup variation, and greater flexibility in production.

KURZ 2D Inkjet: Precise metallization – even on demanding substrates

With the KURZ 2D Inkjet process, UV adhesive is applied to the reverse side of the transfer foil — similar to cold transfer — then cured and transferred to the substrate. This enables brilliant metallization effects with outstanding precision and process stability across a wide range of substrates. Discover how the KURZ 2D Inkjet process delivers unmatched precision and substrate versatility.

What is KURZ 2D inkjet technology?

2D digital metallization on virtually any substrate

Thanks to KURZ’s patented 2D inkjet technology, you can achieve brilliant metallic embellishment across an exceptionally wide range of substrates — from unsupported films to textured and uncoated papers. Even challenging materials can be finished with ease, opening the door to new applications and high-value product lines.

Flexible and precise digital embellishment workflow

This digital technology precisely controls adhesive placement without conventional printing plates. Ideal for diverse substrates, it ensures perfect metallic application on every run — fast, flexible, and efficient

Patented innovation for high-impact effects

KURZ’s proprietary process enables precise application of both large-area metallization and delicate filigree details, all while remaining fully overprintable. The result: Standout finishes, high gloss levels, and eye-catching effects that elevate your brand presence — whether for premium labels and packaging, commercial print, or personalized Web2Print campaigns

How it works: Reliable on every substrate

Step 1: Adhesive application

The inkjet technology applies UV adhesive precisely and accurately to the reverse side of the transfer foil.

Step 2: Transfer foil application

The transfer foil adheres exactly to the adhesive and transfers the metallic brilliance with precision to the target surface.

Step 3: Consistent printing, Reliable results

After transferring, the embellishments adhere reliably to various substrates – from paper to plastic – for brilliant, consistent effects.

Step 4: Optional overprinting

For vibrant, customized metallic colors, simply overprint digitally — enabling maximum creative flexibility.

Ready to dive deeper into 2D inkjet and digital embellishment? Let’s start the conversation.

LEONHARD KURZ Stiftung & Co. KG

Schwabacher Straße 482

90763 Fürth/Germany