Dr. Grandel GmbH

The multi-award-winning family-owned company in its third generation stands for premium-quality cosmetics and healthcare products developed and produced in Augsburg.

An old proverb says: “All good things come in threes.” And even though there are four instead of three variations of the colorful folding cartons of Dr. Grandel PopArt ampoules, the phrase still fits perfectly here, because the digitally enhanced folding boxes of the German cosmetics and makeup brand were recently recognized with an award for the third time.

As early as 2022, the packaging manufacturer Edelmann Group won both the European Carton Excellence Award and the German Packaging Award for the modern and colorfully designed packaging. Award number 3 has now been presented at the Worldstar Global Packaging Awards 2023 of the World Packaging Organization (WPO). The PopArt packaging series by Dr. Grandel impressed the jury in the Digital Packaging category not only for its design sophistication, but above all for its elaborate and yet completely sustainable digital finishing, which was implemented using the DM-MAXLINER 3D from STEINEMANN DPE, a subsidiary of LEONHARD KURZ.

The multi-award-winning family-owned company in its third generation stands for premium-quality cosmetics and healthcare products developed and produced in Augsburg.

Founded in 1913, the family-owned company is one of the world's leading packaging manufacturers for high-quality, innovative, and sustainable packaging concepts made of cardboard and paper for products in the health care, beauty care, and consumer brands markets.

Steinemann DPE - a KURZ company - develops and builds industrial high-end digital printing finishing machines for the graphic industry in the roll and sheet segment.

A limited PopArt packaging design was to be developed for the beauty ampoules of the Augsburg-based company, which would not only be appealing, modern, and inspiring at the point of sale, but also rely on fully recyclable materials and finishing. According to the sustainability concept of the Edelmann Group and Dr. Grandel GmbH, both the outer packaging and the insert were to be made of 100 percent cardboard.

The packaging, each containing five ampoules and a break-open aid, offered numerous design options both inside and out. In order to flexibly tailor the design to the target group and make quick adjustments during the creative design process, the flexible and diverse possibilities of digital finishing were considered from the very start of the project.

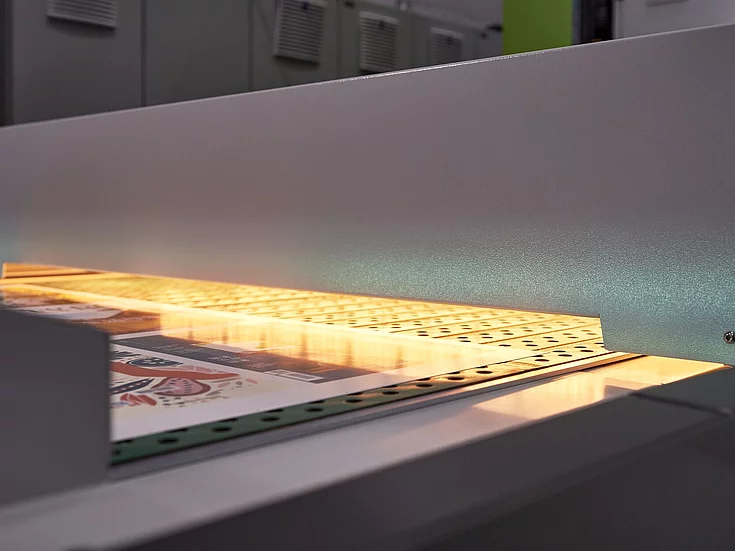

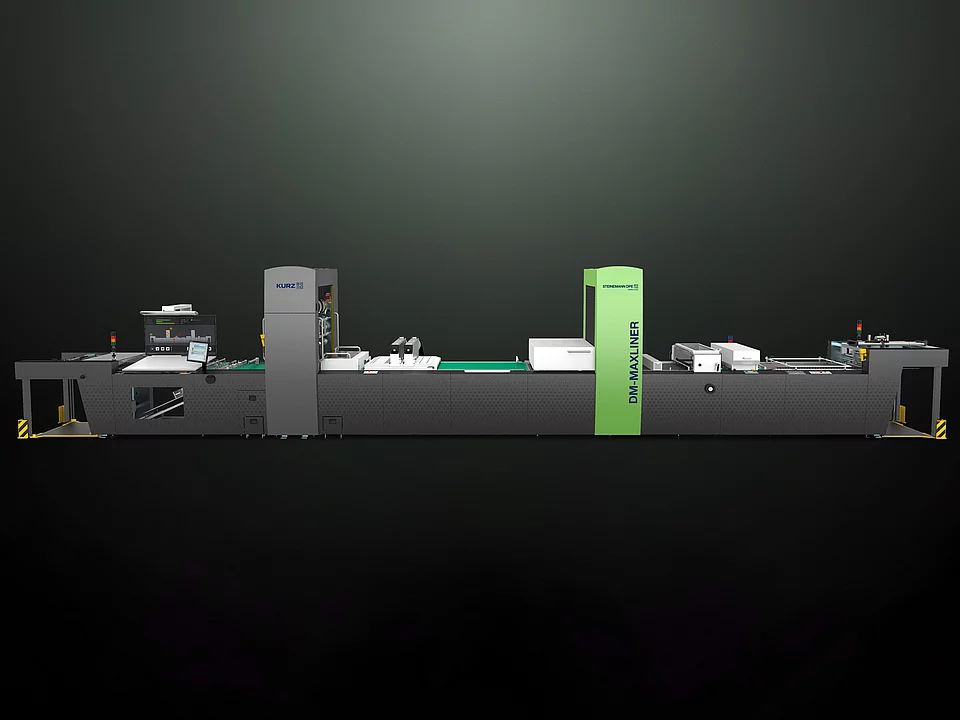

The ambitious project was implemented by the Edelmann Group with the DM-MAXLINER 3D. The complete system developed by KURZ subsidiary STEINEMANN DPE is a milestone in the development of digital finishing. The machine sets new standards in terms of quality, productivity, efficiency, and versatility and, as a complete solution, enables the innovative combination of digital metallization with digital spot and relief coating. This makes it possible, for instance, to create print products with special, tactile 3D looks that are proven to be fully recyclable.

WOW, BOOM, YAY, COOL - lettering and logos on the PopArt packaging series were effectively staged with haptic reliefs and metallizations. Thanks to digital finishing with the DM-MAXLINER 3D, neither hot stamping nor a separate varnish is required for this, which also saves on stamps and varnish plates. This can create an economic advantage for reprints and allows for individual flexible designs without extra costs.

“Dr. Grandel’s exceptional PopArt packaging is fully in line with our aspiration to not only produce folding boxes, but also convey a ‘packaging experience’,”

says Wolfram Hahn, Sales Director France at the Edelmann Group. The hinged lid allows for a great presentation of the products when opening the folding cartons and provides a secure closure with a locking tab with an audible click. The exterior and interior have a matte finish identical in color. The insert, which securely holds the ampoules in place, is also made of cardboard and in the corresponding complementary color.

Stora Enso’s materials for the PopArt packaging series are made from FSC-certified cardboard and are fully CO2 compensated. Even after finishing with the DM-MAXLINER 3D, they are fully recyclable. Claudia Winter, Marketing & PR Director at the Edelmann Group, adds:

“This type of finishing, which is unprecedented on the European packaging market, proves that appeal, elegance, and sustainability are not mutually exclusive, and that it is entirely possible to implement it from an ecological point of view.”

Sustainable production and brilliant print results are the hallmarks of the modern digital print finishing solutions for sheet-fed printing from KURZ and STEINEMANN DPE. For customers, fast start-up times, digital metallization, and an intelligent film-saving system mean lower energy consumption, less production residue, longer machine service life, and thus environmental protection at the highest level.

As part of KURZ’s digital transfer product range, the DM-MAXLINER 3D provides a noticeable simplification of work processes as well as completely new design possibilities for sheet-fed printing. The uniquely flexible system incorporates more than 40 years of experience in machine development. The highly reliable design boasts industry-leading construction and low maintenance costs. In addition, with the DIGITAL METAL® overall concept, KURZ offers a holistic strategy in which machine, software, consumables, and service all come from a single source.

Matte and gloss lacquer finishes

Flat and haptic finishing effects (varnish and metallization)

Reliefs thanks to different coating thicknesses

High printing speeds

Large formats up to B1

Short set-up times

“The high printing speeds, fast set-up times, and outstanding print quality (600 dpi) make the DM-MAXLINER 3D the perfect finishing machine for printers working in packaging, advertising, printing or web-to-print,”

adds Jürgen Stocker, Head of Sales & Product Management at Steinemann DPE. Packaging, leaflets, and personalized prints in large format up to sheet size B1 can be varnished and metallized in the same pass in no time.

Images: Edelmann Group, Dr. Grandel