Case Study with DIN Impresores

- Home

- Newsroom

- Case Studies

- DIN Impresores

Exploring Creative Boundaries: DIN Impresores and the DM-SMARTLINER

DIN Impresores from Madrid has earned a reputation as a first-class printing service provider far beyond the borders of the Iberian Peninsula. Many international agencies and renowned brands are approaching the Spanish family-owned company with challenging requirements.

Founded in 1973 as a bookbinding company, DIN Impresores later became a dedicated job printing company before changing direction and entering the digital and UV offset printing sector. As a true full-service provider, the company now covers the entire print value chain. An in-house graphics department serves as the interface to customers who are increasingly looking for exclusive, high-quality print products. Where other service providers shy away from seemingly impossible tasks, the passionate DIN Impresores team really comes into its own.

The Goal

When speaking to Managing Director Patricia García-Manso, it quickly becomes apparent that the corporate philosophy of DIN Impresores goes far beyond mere standard quality. To this end, the company has already invested heavily in new technology in recent years in order to be able to implement even the most unusual customer requests - with a satisfaction guarantee.

What was still missing in the machine portfolio was a solution for digital metallization on paper and cardboard, which is increasingly in demand in both the job printing and packaging markets. This was a trend that DIN Impresores recognized early on.

The Solution

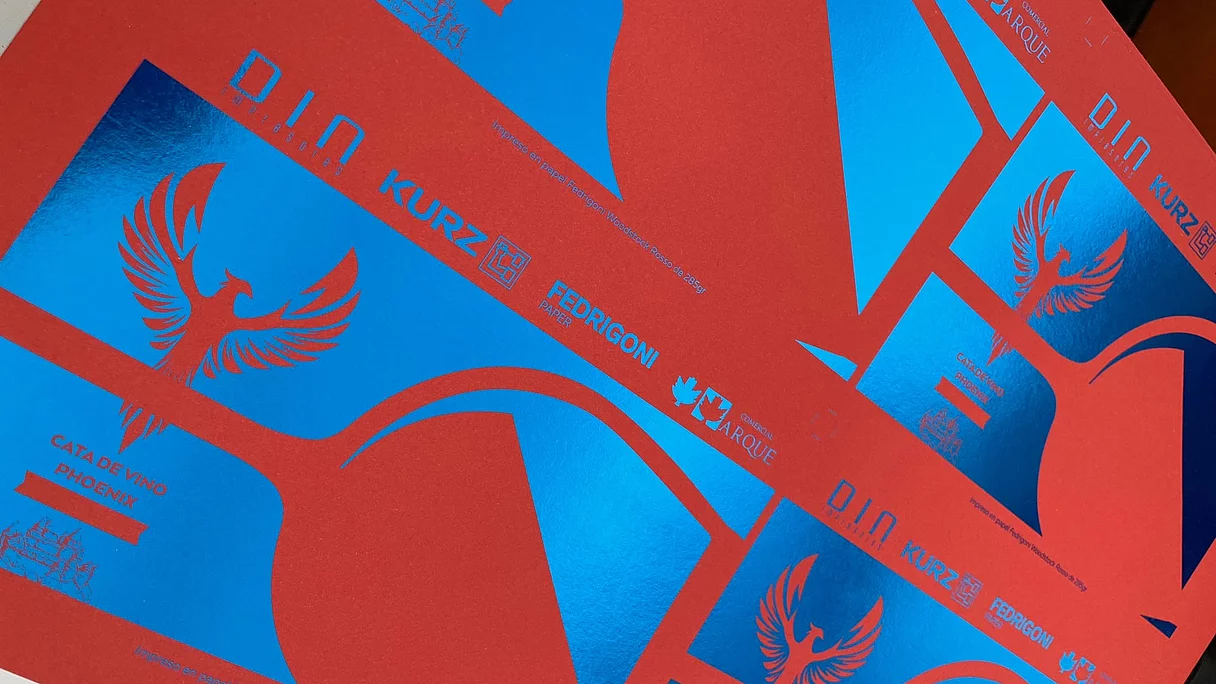

In April 2022, DIN Impresores installed the KURZ DM-SMARTLINER - the first machine in the world to apply metallic finishing quickly and easily to paper and cardboard. The interplay of substrate and printing inks creates the desired wow effects that excite DIN Impresores customers.

Advantages of Digital Metallization with the DM-SMARTLINER from LEONHARD KURZ:

1. Expansion of finishing options to include metallic effects

2. Customizable, individually adaptable to customer requirements

3. Efficient digital printing saves costs and energy

4. Metallization can be easily overprinted

5. High resolution, impressive brilliance

Why KURZ?

“Thanks to custom metal finishing options, the KURZ DM-SMARTLINER opens up a wide range of applications for us. The solution fully meets our expectations in terms of quality, precision, and repeatability,” says Patricia García-Mans.

Another positive aspect for the managing director is that the machine, consumables, and service come from a single source, and that there is a dedicated point of contact for all questions.

With the DM-SMARTLINER, even the smallest runs with very expensive papers and cardboard boxes can be implemented economically and sustainably. Even customer-specific hologram designs are possible - for example, on entry tickets or counterfeit-proof packaging.

Experience Amazing Metallic Effects on Paper and Cardboard with LEONHARD KURZ

- Breathtaking, cost-effective finishing options

- Machine, consumables, and service from a single source

- DIGITAL METAL® overall concept as a holistic strategy

Media Center

Get all the information about our case study here:

- Download case study (PDF)

- Download ‘DM-SMARTLINER‘ brochure (PDF)

- This case study is based on a joint article by the GRAPHISCHE REVUE: Read full article (German)